Last week, BSEE initiated a series of ongoing tests at Ohmsett, the bureau's National Oil Spill Response Research and Renewable Energy Test Facility, to measure the effectiveness of stationary skimmer systems. The skimmers, which are devices that collect and remove oil from the surface of the water, will be tested using multiple oil types in order to determine their Oil Recovery Rate and Oil Recovery Efficiency.

BSEE will use the results of these tests as a comparison to the skimmers' published Nameplate Capacity values, the number currently being used to characterize skimmer performance. The Nameplate Capacity is used in Oil Spill Response Plans to determine whether or not sufficient mechanical recovery equipment is available to respond to a Worst Case Discharge Scenario.

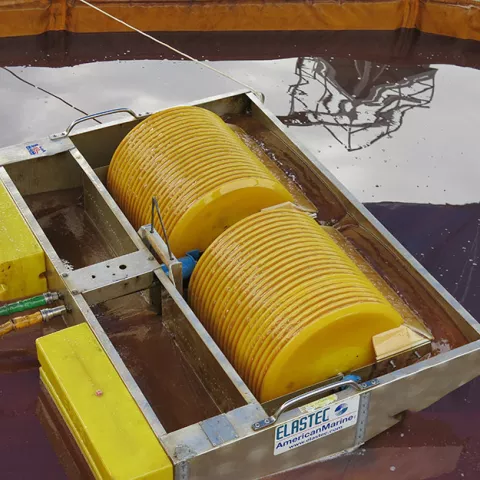

The tests began last week with the Elastec American Marine TDS 118G. This grooved drum skimmer has a shallow draft, is light weight, and is capable of recovering a wide range of oil viscosities. Additional skimmers will be tested in the coming weeks and months using skimmers owned by both BSEE and the U.S. Coast Guard for training purposes at Ohmsett.

BSEE is the principal federal agency funding offshore oil spill response research, and Ohmsett is a key part of the bureau’s Oil Spill Response Research Program. Many of today’s commercially available oil spill cleanup products have been tested at Ohmsett and a considerable body of performance data and information on mechanical response equipment has been obtained there. This information is used by response planners in reviewing and approving facility response and contingency plans. More information about BSEE's Oil Spill Response Research Program can be found here.