BSEE inspectors walk toward an Agusta Westland A109E Power helicopter operated by ERA Inc. prior to departure from New Orleans Oct. 24. ERA is the offshore helicopter contractor that transports BSEE inspectors during annual, unannounced and other inspections.

By Guy Hayes

January 17, 2017

The backbone of the Bureau of Safety and Environmental Enforcement (BSEE) is the inspector workforce. Like a non-commissioned officer in the military, these dedicated men and women set the standard and uphold the core values of the organization. They are on the front line, ensuring that the goal of BSEE’s mission - the safe and responsible development of our nation's domestic offshore energy resources - is enforced.

BSEE’s has approximately 130 inspectors, who are located in Alaska, California, Louisiana and Texas. They are experts with a noble mission–protecting both workers and the environment on the Outer Continental Shelf.

As a public affairs officer for BSEE, I’ve witnessed the bureau’s inspectors as they perform their job. From our Pacific offices in Camarillo, California, to the Gulf of America to the frozen north of Alaska’s Beaufort Sea, I’ve observed inspectors who work with the offshore oil and gas industry to instill a culture of safety.

I’ve always been intrigued and impressed by their collaborative effort to reach their goals. A recent trip I took to the Gulf of Mexico, however, really opened my eyes. It was there that I witnessed how well our inspectors work alongside, not against, industry to ensure operators follow acceptable industry practices and federal safety standards.

My latest travels with two BSEE’s inspectors began on a Monday morning in New Orleans as ERA aviation pilot A.J. Bell increased the throttle on the twin-turbo engine Agusta Westland A109E Power helicopter. I was sweating. As an Alaskan on a story assignment for BSEE, I could already feel the beads of perspiration rolling down the small of my back. It was October 24, a cool day according to Bell, but not for someone who just left subfreezing conditions. Clutching my camera tightly, I heard a static voice come over the headset clearing us for take-off.

With the rotor blades at full speed, our helicopter gently shook as we lifted off the landing pad. Hovering in place, the sun cut through the front windows before we changed direction and headed towards the Gulf of America.

Climbing to an altitude of 3,000 feet, I began to relax and enjoy the views. A casual conversation ensued, and was soon joined by everyone onboard. In addition to Bell, I was accompanied by BSEE inspectors Joe Sonnier and Frank Musacchia.

An ERA mechanic inspects an Agusta Westland A109E Power helicopter on a levee bordering the Mississippi River Oct. 24 following an in-flight emergency that required the pilot to land the helicopter in a rural community south of New Orleans.

My assignment was to accompany Sonnier and Musacchia offshore to board the Stena Forth, a drillship managed by Stena Drilling Ltd., which was drilling for Hess Corporation at the Tubular Bells site. Their mission was to inspect the well operation. I’ve accompanied BSEE inspectors in the Arctic before, but this would be my first flight offshore with BSEE inspectors in the Gulf of America.

Joe and Frank were two experienced inspectors from Louisiana, and I liked them both immediately. As the minutes passed, we chatted about our kids, outdoor pursuits and laughed like we were close friends. We quickly discovered we had plenty in common and our conversations relaxed my nerves, settling me in for the hour-long flight ahead.

The streets of New Orleans faded into the background and I focused my attention on the dark-black water and deep-green landscape of the Louisiana bayous that lay in front of us. The area was cut by a single road that snaked its way across the watery view. The sight was breathtaking, different in subtle ways from Alaska, and I appreciated the opportunity to take it all in. Things grew quiet and whatever nerves I had been experiencing dissolved into a feeling of serenity.

Then the peaceful silence broke. I saw Sonnier point and then quickly snatch the flight manual next to his seat.

As I sat in the left backseat I watched Bell methodically check his gauges while Sonnier worked to assist him. My shoulders grew tight.

“The master warning light is on and the transmission temperature is high and climbing rapidly,” Sonnier voiced through the headsets.

This was bad. Really bad. I knew enough about helicopters to know that a transmission failure would result in us dropping like a rock. We were twenty minutes into our flight, and Bell was in a fight to keep the helicopter airborne before the transmission overheated and potentially seized.

“WARNING! WARNING!,” a computer-generated voice exclaimed over my headset. The master warning light had been followed by an audible warning that was blaring over my headset

Without hesitation, Bell banked the helicopter to the left and called out over the headsets that we were going to attempt to fly back to Belle Chasse Naval Air Station. My mind raced. There was nothing I could do, except remain quiet and watch Bell deal with the situation I assumed he’d been trained to handle.

“The temperature is still climbing,” Sonnier called out to Bell as he continued to turn the helicopter 180-degrees in an effort to fly the 15-nautical miles back to Belle Chasse.

“WARNING! WARNING!” the voice repeated in my headset as red lights flashed rapidly on the A109E instrument panel. Then, in all that chaos I heard the juxtaposition of a calm voice. It was Bell, and in a manner that was both professional and steady he said, “We’re not going to make it back to Belle Chasse, we have to land now.”

Bell spotted a gravel road on top of a levee that paralleled the Mississippi River on the left and a few houses on the right.

After descending quickly, Bell gently landed the craft on the gravel a few hundred yards away from a busy road that cut through Louisiana’s marshes and bayous.

The adrenalin rush was over, and I sighed deeper than I can remember ever doing before. Bell shut down the engine and we quickly evacuated the helicopter.

“That’s the most scared I’ve ever been in my life,” Sonnier exclaimed. “We’re done flying for today.”

I was quiet for a moment, contemplating Sonnier’s remark. He’s flown a lot down here, and this was my first Gulf flight.

Over the next few hours, we assessed the situation and waited to be picked up by an emergency crew that was en route. Reliving the moment, we dealt with the stress through humor, but were also keenly aware of the significance of the event and how well Bell and Sonnier handled the situation.

Later that day, after several phone calls and emails alerting my supervisor and family to our situation, I sat in my hotel room and contemplated the events that had unfolded. As a public affairs officer, I was on assignment to accompany inspectors offshore to a platform so I could tell their story. Now I had experienced something with them that revealed their willingness to take risks in order to protect offshore workers and safeguard the environment. I had one experience, but BSEE inspectors do this every day. Every morning, depending on weather, they arrive at a helicopter to fly offshore. What I experienced wasn’t a typical event by any means, but every time they board a helicopter they face hazardous situations. Helicopter fatalities are not common, but they do happen. In fact, they rank as a leading cause of fatalities among offshore workers, along with explosions/fires and lifting incidents.

Four-thirty came early the next morning as my alarm woke me from a restless night’s sleep. I had tossed and turned as I relived the helicopter flight, but had to get-up early to drive to Houma, Louisiana, an hour south of New Orleans

It was a do-over, and I was scheduled to fly again with inspectors from BSEE’s Houma District, one of five districts in the Gulf of Mexico Region. We were scheduled to fly to a deepwater facility roughly 100 miles offshore.

When I arrived at 6 a.m., I was still reeling from my experience the day prior, but knew I needed to get back on the horse and keep going. They already knew who I was and heard about my experience the day prior.

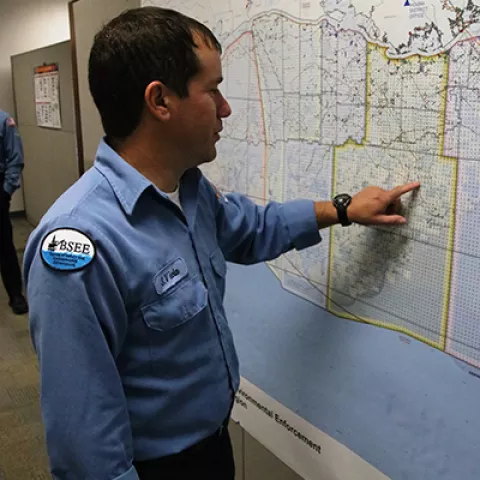

BSEE Lead Inspector Sammy Viola points to the location of Front Runner, a deep-water facility in the Gulf of America, at BSEE’s Houma District office prior to departing for an inspection of the facility Oct. 25.

“Hope you’re not bad luck,” one inspector said as I walked in the door. He chuckled, but also seemed serious at the same time. At least that was what I thought in that instant.

After discussing options for the day, I was introduced to BSEE Lead Inspector Sammy Viola and his partner, Inspector Greg Liner.

“We’re headed to Front Runner, a truss spar platform in Green Canyon block 338 operated by Murphy Oil,” said Viola, pointing to the map for my benefit.

Viola came to BSEE as an intern seven years prior and had moved up to the position of lead inspector. He was a friendly guy, married with two young children -- a two-year old and the other only seven months old. He has lived in southern Louisiana his whole life. He’s also a Coast Guard reservist and serious about the importance of doing his job to the best of his ability, all day, every day.

“I believe in service,” he told me. “As a BSEE inspector and Coast Guard reservist, I feel like I’m making a difference in our community and want to make sure my kids have a great place to live when they grow-up. Greg and I are just two of many BSEE inspectors who work hard to make sure industry is held to the highest standard.”

Liner was fairly new to the job with only 15-months under his belt, but was definitely not your typical greenhorn. A career firefighter, Liner served 28-years and attained the rank of captain before retiring in 2010. In 2012, Liner set his sights on college, earning his degree in petroleum process technology at age 53. After graduating, he served a short stint within the oil and gas industry and was hired as a BSEE inspector in 2015.

“As a firefighter, we had a certain camaraderie and I missed it,” Liner said. “I went to school, looking for a new opportunity and career. I never thought I’d feel that sense of belonging again, until I joined BSEE — it has a calling and I’m lucky to feel that sense of camaraderie again.”

Peering over the shoulder of BSEE Inspector Sammy Viola, Front Runner platform can be seen on the horizon during final approach Oct. 25 as part of an inspection to oversee operations.

Both Viola and Liner are down-home American blue-collar workers who share similar stories. They both grew up in Morgan City, Louisiana, and their parents worked in the oil and gas industry. Their friends and families-in fact everyone they know-grew up tied to the industry. They have a deep appreciation for what it’s brought to their communities, but they have an equal reverence when it comes to the importance of safety and environmental stewardship.

“My parents worked as regulatory compliance specialists in the industry for 35 years,” said Viola. “It takes a certain type of personality to work out there for weeks on end, and I have an immense appreciation for what it takes to ensure safety on the job. When I was trying to find a career path, I knew I wanted to be in regulatory compliance. It’s important to me because there’s a lot of stuff going on out there, and the reason I go out there every day is to make sure those guys go home at night. I couldn’t walk away from something unsafe. I wouldn’t sleep if I did.

Front Runner, a truss spar facility operated by Murphy Oil, is located 85 miles offshore in the Gulf of America and is capable of producing 60,000 barrels of oil and 110 million cubic feet of gas per day.

Nodding his head, Liner agreed saying, “Both my parents also worked in the oil industry, so I know what it’s like to have a vested interest in safety for offshore workers. It’s critical that we educate people to do the right thing, so everyone goes home to their families."

Finishing the conversation, we boarded a van full of BSEE inspectors and made the short drive to the Houma airport. My mind raced in anticipation of another helicopter flight, but as I listened to the inspectors argue about the World Series, college football and the NFL, I found myself starting to relax. They joked and bantered until the van arrived at the airport, where they quietly gathered their gear and headed towards their respective helicopters.

BSEE Inspector Sammy Viola points at a computer monitor where a Murphy Oil representative oversees subsea infrastructure from the Front Runner control room. Murphy Oil employees oversee operations from the control room 24 hours a day to ensure they can shut down the flow of oil and gas in an emergency.

With rotor blades slicing the air, I was soon flying again towards open water over the Gulf of America. Gripping my seat belt, I fumbled with my camera to stay busy and asked Viola and Liner questions to keep my mind occupied. Then I began settling into the hour-long flight as I listened to the radio chatter between pilots. The number of helicopters in the air at that moment made me think again about the dangers these inspectors face each of the five days a week they are flying offshore to do their job.

“Make sure you keep a look out your window,” said the pilot over the headsets. “If you see something call-it out, so we can try and avoid any issues.” Not wanting to disappoint him, I looked for high flying birds, other aircraft or anything else that looked out of place. I also quickly understood why our inspectors fly offshore daily. Staring out the window, I could see numerous drillships, platforms and support facilities covering the bright blue landscape. Some appeared small and others seemed as large as skyscrapers. In every direction they went on into the horizon.

“Some of these facilities have been out here for more than 60-years,” Viola pointed out to me as we passed several platforms close to each other. “They are still producing, and we come out to each one of these facilities annually, to ensure the operators are following the regulations.”

BSEE Inspectors Greg Liner (center) and Sammy Viola speak with Murphy Oil employee Calvin Solomon in front of a coil tubing operation during inspections on Front Runner Oct. 25.

A short time later, we were circling our destination, Front Runner. At first it appeared to be a small dot on the horizon, but as we circled her on our approach, I could see it was a massive facility.

After a gentle landing on the helipad, I unbuckled my harness and stepped onto the platform where we were greeted by a Murphy Oil employee. He eagerly led us down three flights of steep stairs to the main office. Once inside, we received a series of briefings from the Murphy Oil staff. They covered safety, evacuation procedures and facility capabilities. Viola and Liner then quickly briefed me on the scheduled inspection.

“We are here to review temporary well flowback equipment to ensure all the required safety systems meet federal regulations,” said Viola. “Our engineers reviewed this paperwork, and we need to make sure they are following these procedures.”

In their hands, Viola and Liner had drawings submitted to BSEE engineers 14 days earlier. The paperwork depicted work commencing at the facility, illustrating all the components in accordance with regulations. It was the responsibility of Viola and Liner to verify that the diagrams and actual work matched, and they needed to test all safety devices to ensure the set-up was done correctly.

“When they perform these operations, it’s outside of normal day-to-day business, so we want to make sure it’s all installed correctly,” said Liner. “If it isn’t done correctly, we could have a serious incident, and the lives of the people on this platform could be at risk.”

Viola added, “Anytime you add equipment to an equation, it’s pretty significant to the operation. We need to make sure everything is in accordance with regulations.”

Over the next few hours, Viola and Liner walked around the platform accompanied by Murphy Oil staff and third party contractors from Stric-Lan, the company responsible for installing and managing the temporary equipment. With my eye firmly behind the camera lens, I watched as they meticulously combed over the paperwork, oversaw pressure tests, and requested information about the equipment set-up on the platform to verify the diagrams. There’s lots of noise on an offshore platform, so I could only catch some of what was being said.

BSEE Inspectors Sammy Viola (left) and Greg Liner closely monitor a pressure gauge held by Murphy Oil employee Calvin Solomon during a pressure test of temporary equipment on Front Runner, a deep-water facility in the Gulf of America.

Taking a moment to educate me, Liner raised his voice quite a bit to get my attention. Pointing overhead he almost shouted so that I could hear him: “That’s a coil tubing unit. They’re using that to shift reservoir zones in the well, and the well flowback equipment we’re inspecting allows them to capture any fluids they may encounter during the operations and pump it back into the main facility operations."

Viola who was closely listening added, “That’s important because if it’s not installed correctly, there is a risk of over-pressure, which could lead to a spill or explosions. That puts people at risk and the environment at risk, so it’s critical we come out here to verify proper installation.”

I got it. Inspecting these components protects the men and women who work and live on this facility. Like the inspectors, offshore workers come out here to do a job, but the workers often spend weeks in the field. It’s all done for their families back home, the ones they expect to return to when a helicopter takes them back to land. That’s why Viola and Liner fly out to facilities each day: to make sure complacency doesn’t set in and that a culture of safety is the norm 24-hours a day on every facility.

“I truly believe that people want to do the right thing,” Liner hollered over the crane operations in the background. “They want to go home to their families like everyone else. It’s our job to educate people to follow the regulations, whether they agree or disagree, to ensure this attitude of safety and environmental protection is ingrained into their culture.”

BSEE Inspectors Sammy Viola (center) and Greg Liner review paperwork submitted by Stric-Lan contractor Brian Landry during an inspection on Front Runner Oct. 25.

What he said wasn’t entirely new to me. It’s part of the BSEE culture and mission, and they are words I hear regularly in some similar form, “safety and environmental protection.”

Wrapping up the inspection, Viola and Liner logged their findings and met with the Murphy Oil foreman and third party contractor to discuss corrective actions. Armed with a number of enforcement tools, Viola and Liner, like all inspectors, can issue Incidents of Non-Compliance, BSEE’s version of a citation, to require operators to correct violations. When needed, BSEE can pursue civil penalties and even stop operations. In fact, during the 2016 federal fiscal year BSEE issued more than $2.4 million in fines and issued 138 facility shut-in Incidents of Noncompliance.

“No major concerns today,” said Viola. “But we found a few minor issues that we needed to work through. We’ll ensure they correct those issues to stay in compliance with federal regulations.”

Boarding our helicopter flight back to Houma, I contemplated all that I’d been through in the last two days and how eye-opening it was to experience a day in the life of a BSEE inspector in the Gulf of America Region.

With more than 2,200 facilities and about 26,000 miles of pipeline in the Gulf of America, we ask a lot of these men and women. Without pause they continue to deliver, providing stringent, but fair oversight of activities on the Outer Continental Shelf in the Gulf of America. They’re the real deal, true stewards of America’s offshore resources and are committed to their jobs.

When I traveled home to Alaska later that week, I couldn’t help but think of words spoken by BSEE Director Brian Salerno on more than one occasion: “People are our most valuable resource.” I now have a better understanding of what he meant by that, having spent a few days with inspectors like Joe, Frank, Sammy and Greg. They are BSEE’s most valuable resource and I’m proud to serve with them.